The Future of Design: How CAE is Transforming Engineering Solutions

- Milestone PLM Solutions

- Oct 25, 2024

- 3 min read

In the rapidly evolving landscape of engineering, Computer-Aided Engineering (CAE) is redefining the design process. As industries increasingly prioritize efficiency, sustainability, and innovation, CAE tools empower engineers to push the boundaries of what’s possible. With CAE, engineers can simulate real-world conditions digitally, allowing them to develop optimized, high-quality products in shorter timelines. This article explores how CAE is transforming the future of engineering solutions, touching on its benefits, applications, and the challenges it helps overcome.

Understanding Computer-Aided Engineering (CAE)

Computer-Aided Engineering (CAE) encompasses the use of software to aid in engineering analysis tasks. The CAE ecosystem includes tools that facilitate simulation, validation, and optimization of products and processes. As an integral part of modern product lifecycle management (PLM), CAE supports the complete journey from design and development to manufacturing. Unlike traditional methods, where physical prototypes are the norm, CAE enables engineers to use digital prototypes, offering faster and more accurate results.

The Power of Simulation in Design

One of the defining features of CAE is its ability to simulate real-world forces, which can predict how products will perform under specific conditions. Whether it’s a load-bearing bridge, an aircraft’s aerodynamics, or even a mobile phone’s drop test, CAE allows engineers to visualize and modify designs based on highly accurate data. This capability goes beyond simple CAD design, opening up new possibilities in optimizing design for performance, cost-efficiency, and sustainability.

Key Advantages of CAE Simulation:

Cost Savings: By reducing the need for physical prototypes, CAE tools significantly lower design and testing costs. Engineers can address design issues before manufacturing, resulting in fewer errors, lower material costs, and minimal waste.

Enhanced Performance: CAE software enables engineers to iterate quickly, testing various materials, configurations, and dimensions. This data-driven design approach yields highly efficient, performance-optimized products that can withstand real-world stresses and demands.

Sustainability: With CAE, companies can design with environmental impact in mind. Reducing material waste, optimizing for energy efficiency, and minimizing resource use during manufacturing are all achievable with CAE.

The Integration of AI with CAE

Artificial Intelligence (AI) and Machine Learning (ML) are adding new layers of capability to CAE tools. By analyzing data from past designs, AI can suggest optimized solutions and even predict potential design failures. For instance, generative design algorithms can propose hundreds of design alternatives, allowing engineers to select the best options based on predefined criteria.

Through the combination of AI and CAE, engineers are creating designs that would have been nearly impossible to develop manually. This automation not only saves time but also opens doors to innovations in complex fields like automotive and aerospace, where design precision and safety are paramount.

Real-World Applications of CAE

Automotive Industry: In automotive engineering, CAE is essential for designing safer, lighter, and more fuel-efficient vehicles. Engineers use CAE tools to test the durability of materials, simulate crash impacts, and optimize aerodynamics, contributing to the ongoing evolution of electric and autonomous vehicles.

Aerospace: CAE is a critical asset in aerospace, where precision and safety are fundamental. From testing aerodynamic efficiency to simulating high-altitude stress, CAE tools are pivotal in designing lightweight yet durable components that meet stringent regulatory standards.

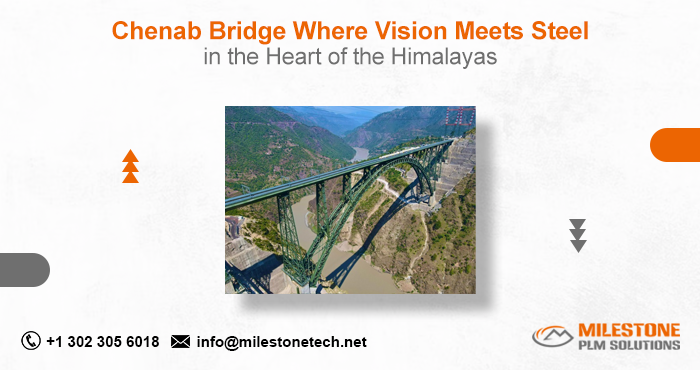

Construction and Infrastructure: Civil engineers leverage CAE to simulate structural loads, environmental conditions, and material behavior over time. By analyzing factors like wind loads, seismic activity, and temperature fluctuations, CAE helps ensure the safety and durability of buildings, bridges, and other infrastructure projects.

Healthcare: In the biomedical field, CAE is used to design medical devices and prosthetics tailored to individual patients. The simulations enable engineers to test performance in virtual environments, minimizing the risks associated with device failure.

Overcoming Engineering Challenges with CAE

Engineering challenges often revolve around managing complexity, adhering to regulatory standards, and minimizing environmental impacts. CAE solutions address these challenges by allowing detailed simulations that can analyze potential issues before manufacturing. CAE also supports collaborative work environments where interdisciplinary teams can collaborate on a unified digital platform, ensuring cohesive designs that meet diverse technical and regulatory requirements.

Future of CAE in Engineering Solutions

As CAE continues to evolve, we can expect advancements in real-time simulations and cloud-based CAE platforms, which will facilitate faster and more accessible analysis. Engineers will be able to simulate increasingly complex systems, further reducing reliance on physical prototypes and accelerating product development cycles.

Additionally, as sustainability becomes a critical focus, CAE will play an increasingly central role in developing eco-friendly designs. With features like lifecycle analysis, engineers can evaluate a product’s environmental impact over its lifespan, making CAE a key player in sustainable engineering.

Conclusion

Computer-Aided Engineering (CAE) has established itself as a cornerstone of modern engineering solutions, revolutionizing design and analysis across industries. By enabling sophisticated simulations, cost savings, and sustainable designs, CAE tools empower engineers to create groundbreaking products that meet the demands of the future. As CAE technology continues to advance, its role in driving innovation, efficiency, and sustainability will only grow, setting new standards for what engineering can achieve